Anti Corrosive Coating

900 INR/Liter

Minimum Order Quantity : 20 Kilograms

Delivery Time : 7 Days

Usage Industrial

Size Different Sizes Available

About this product

Stanvac Starblaze anti corrosion Surface tolerant coating is a two-component high build MIO based immersion grade

mastic coating offering excellent chemical, corrosion & abrasion resistance in severe industrial environments.

Acid Area Coating

650 INR/Ten Gross

Minimum Order Quantity : 100 sq ft Square Yards

About this product

Starblaze 75C03 is with 100% solids consisting of Novolac resin with a UV & Moisture tolerant advanced cycloaliphatic curative coating. Outstanding resistance to both concentrated mineral acids (98% Sulfuric, 33% Hydrochloric, Aqua Regia.)as well as organic acids (Acetic acid, Fatty acids.) and also concentrated oxidizing acids (50% Nitric acid, 10% Hydrofluoric Acid). It offers an excellent protection to concrete surfaces

Superior Protection Against Corrosive Environments

Acid Area Coating safeguards industrial surfaces with its high resistance to acids and chemicals. By using an advanced, acid-resistant epoxy resin, it ensures your facility is protected from corrosive attacks, prolonging the lifespan of equipment and infrastructure. This long-lasting barrier is ideally suited for environments requiring stringent acid-proof specifications.

Flexible Application and Customization

With options for brush, roller, or spray application, Acid Area Coating adapts to different project needs, enhancing ease of use. Thickness and color can be tailored to customer requirements, making it suitable for a wide range of substrates. Its customizable nature offers versatility for both standard and unique industrial environments.

Efficient Installation and Maintenance

The coating dries to the touch within 4-6 hours and reaches full cure in 7 days at ambient temperature, minimizing downtime. Equipment can be cleaned easily with suitable solvents immediately after use, while proper storage in a cool, dry place ensures the product retains quality throughout its 12-month shelf life.

Superior Protection Against Corrosive Environments

Acid Area Coating safeguards industrial surfaces with its high resistance to acids and chemicals. By using an advanced, acid-resistant epoxy resin, it ensures your facility is protected from corrosive attacks, prolonging the lifespan of equipment and infrastructure. This long-lasting barrier is ideally suited for environments requiring stringent acid-proof specifications.

Flexible Application and Customization

With options for brush, roller, or spray application, Acid Area Coating adapts to different project needs, enhancing ease of use. Thickness and color can be tailored to customer requirements, making it suitable for a wide range of substrates. Its customizable nature offers versatility for both standard and unique industrial environments.

Efficient Installation and Maintenance

The coating dries to the touch within 4-6 hours and reaches full cure in 7 days at ambient temperature, minimizing downtime. Equipment can be cleaned easily with suitable solvents immediately after use, while proper storage in a cool, dry place ensures the product retains quality throughout its 12-month shelf life.

FAQ's of Acid Area Coating:

Q: How is Acid Area Coating applied to industrial surfaces?

A: Acid Area Coating can be applied using a brush, roller, or spray, depending on the size and needs of your project. Before application, surfaces should be adequately prepared and primed with an acid resistant epoxy primer for maximum adhesion and protection.Q: What benefits does this coating provide in acid-prone environments?

A: This coating offers high resistance to acids and chemicals, excellent adhesion to both concrete and steel, and anti-corrosive, waterproof, and long-lasting protection. It helps maintain industrial infrastructure by reducing the risk of chemical damage.Q: What is the recommended process for cleaning application equipment?

A: It is important to clean all application equipment with a suitable solvent immediately after use to prevent the epoxy from hardening and ensure the longevity of your tools.Q: When can the coated surface be fully put into service after application?

A: Although Acid Area Coating becomes surface dry in 4-6 hours, it reaches full cure in 7 days at ambient temperature. It is recommended to wait for full cure before exposing the surface to harsh chemicals or heavy mechanical stress.Q: Where should the product be stored for optimum shelf life?

A: For best results, store the Acid Area Coating in its sealed container in a cool, dry place, away from direct sunlight. Proper storage ensures the product remains effective for up to 12 months.Q: What customization options are available for the coating?

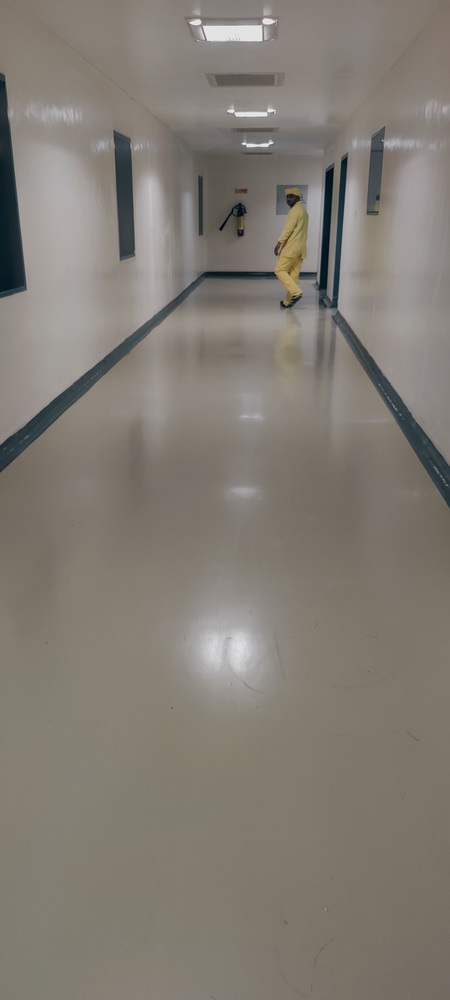

A: Customers can choose from standard grey or request custom colors. The coating's thickness is also customizable based on project requirements, providing flexibility for various industrial applications.Pharmaceutical Epoxy Flooring

1500.0 INR/Square Yard

Minimum Order Quantity : 100 Square Yards

About this product

Find incomparable quality and unbeatable discount offers on Pharmaceutical Epoxy Flooring, a gorgeous solution tailored for the pharmaceutical sector. Garnering favorable reviews from distributors, exporters, suppliers, and traders across India, this uncommon epoxy resin floor provides exceptional compressive strength exceeding 60 MPa and superior bond strength above 1.5 N/mm. With a seamless, glossy surface finished in sophisticated grey, its highly chemical resistant, easy to clean, and engineered for long service life. Its high abrasion resistance, customizable slip resistance (R9-R12), and low VOC content ensure safety and compliance in demanding environments. Choose durability and elegance for pharmaceutical facilities, hospitals, and laboratories.

Recommended Uses and Direction of Application

Pharmaceutical Epoxy Flooring is applied using a trowel or roller, ensuring a seamless and uniform surface. Before application, the substrate must be clean and level. This flooring is widely used in pharmaceutical manufacturing units, hospitals, and laboratories, where hygiene and durability are paramount. Its favored as a protective and decorative layer due to its chemical resistance and ease of cleaning. Available in thicknesses from 2 to 4 mm, it offers both functional and aesthetic advantages.

Sample Policy and Payment Terms for Pharmaceutical Epoxy Flooring

Upon request, sample pieces of Pharmaceutical Epoxy Flooring can be arranged for early arrival, helping clients assess quality before making large commitments. Our sample policy ensures smooth logistics and accessible valuation, streamlining the procurement process. Flexible payment terms provide convenience for traders, distributors, and suppliers. Whether youre placing a small order or organizing bulk shipments, our trusted supply chain guarantees reliable and timely delivery throughout India.

Recommended Uses and Direction of Application

Pharmaceutical Epoxy Flooring is applied using a trowel or roller, ensuring a seamless and uniform surface. Before application, the substrate must be clean and level. This flooring is widely used in pharmaceutical manufacturing units, hospitals, and laboratories, where hygiene and durability are paramount. Its favored as a protective and decorative layer due to its chemical resistance and ease of cleaning. Available in thicknesses from 2 to 4 mm, it offers both functional and aesthetic advantages.

Sample Policy and Payment Terms for Pharmaceutical Epoxy Flooring

Upon request, sample pieces of Pharmaceutical Epoxy Flooring can be arranged for early arrival, helping clients assess quality before making large commitments. Our sample policy ensures smooth logistics and accessible valuation, streamlining the procurement process. Flexible payment terms provide convenience for traders, distributors, and suppliers. Whether youre placing a small order or organizing bulk shipments, our trusted supply chain guarantees reliable and timely delivery throughout India.

FAQs of Pharmaceutical Epoxy Flooring:

Q: How is Pharmaceutical Epoxy Flooring installed?

A: Pharmaceutical Epoxy Flooring can be installed using either a trowel or a roller, following proper surface preparation to ensure a strong, seamless finish.Q: What are the main benefits of using this epoxy flooring in pharmaceutical environments?

A: The flooring offers exceptional chemical resistance, excellent compressive strength, customizable slip resistance, and ease of cleaningmaking it ideal for spaces where cleanliness and safety are critical.Q: What is the typical curing time after installation?

A: After application, the flooring requires a curing period of about 24 to 48 hours, depending on ambient conditions for full hardness and durability.Q: Where can this epoxy flooring be applied?

A: Pharmaceutical Epoxy Flooring is designed for use in pharmaceutical industries, laboratories, and hospitals where a robust, hygienic, and seamless surface is essential.Q: What is the standard service life of this epoxy system?

A: The service life of Pharmaceutical Epoxy Flooring is typically 8 to 10 years when properly installed and maintained under normal operating conditions.Explore Additional Categories

Contact Us

Our Products

Our Products